MINE OPTIMISATION PROGRAM TO EVALUATE ECONOMICS OF DSI SNAKE HIGH ANGLE CONVEYOR IN OPENCAST MINE

ECONOMICS OF DSI SANDWICH HIGH ANGLE CONVEYOR

AND ITS COMPARISON WITH IPCC & DUMPER

TRANSPORT IN OPENCAST

By Shyamal Kumar Bag

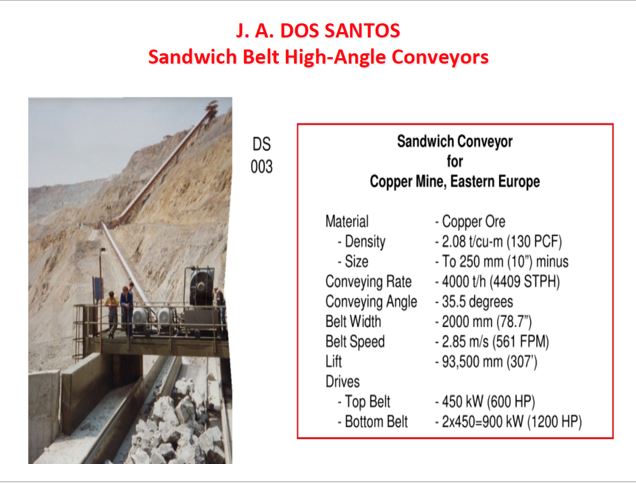

DSI Sandwich High Angle Conveyor (HAC) is a special type of conveyor system, where the material is hugged between the top and bottom conveyor belts and carried at any steep angle up to 90 degrees. The system is able to elevate material high in a limited horizontal space. This system can be imagined as an elevator in a high-rise, where one can easily reach the top floor in minimum time and without effort avoiding the staircase. Since DSI Snake HAC angle covers the material from both top and bottom, hence, there is no chance of dust generation during operation.

In deep opencast mine, the DSI HAC can be an ideal & most economic system for transport of material from pit-bottom to surface through the sidewall of mine (35 to 50 degree)as an alternative to dumper transport or in-pit conveyor system runs through haul road, where the gradient is limited to 1 in 15 or so. In opencast mine, transport cost is around 60% of total mining cost. Hence, the adoption of the DSI HAC system especially in deeper opencast mines shall save huge mining costs.

In the present paper, the author has prepared economic comparisons between three mine transport systems as follows:

a) System I - DSI SNAKE HAC, In-pit crusher (IPC) at pit bottom, and short dumper transport from the coal face to IPC/DSI HAC.

b) System II - Short dumper travel from the coal face to IPC at pit bottom, In-pit conveyor from the pit bottom to surface following the haul road.

c) System III - Dumper transport from the pit bottom to the surface crushing plant.

For the elaboration of the location of DSI HAC, In-pit conveyor and dumper transport in an opencast mine following opencast mine layout is shown.

SOME PHOTOGRAPHS AND IMAGES OF DSI SNAKE HAC APPLICATION THROUGH SIDEWALL IN OPENCAST MINE

MINE OPTIMISATION PROGRAM TO EVALUATE SPECIFIC SYSTEM COST (RS/TE) AND DISCOUNTED CASH FLOW FOR TWENTY YEARS FOR ALL THE THREE SYSTEMS

Both the above parameters are very important to evaluate and compare different systems. The specific cost/te indicates various cost elements within total system cost/te and the discounted cash flow analysis the impact of initial investment, discount rate, escalation rate along with the progress of mine, overhauling cost at a pre-determined interval and also replacement cost of equipment at the end of their economic life. It helps to choose the most economic system. The author has developed the program based on various statistical data and also calculation norms for HEMM by CIL/CMPDI and hence, can be relied upon. The Author has not found any similar calculations/programs presented or practiced elsewhere, even by CMPDI and as such this program is unique.

Comparisons are done for three cases based on annual production of 10 mtpa and with three mine depths i.e, 100 m, 150 m, and 200 m. Three cases shall amply clarify the economics and with graphical analysis for easy understanding.

From the results, it can be easily concluded that with an increase of mine depth, the DSI HAC is more and more economical over the other two alternatives, and due to huge savings over dumper transport system, the payback period for investment against DSI HAC shall be only one year. It may not be out of place to mention here that with the increase of annual production of more than 10 mtpa the savings for DSI HAC will be more significant.

The Author is attaching the screenshots of various calculation pages. The program is having very wide flexibility to change any parameters as shown in the Summary page and the program has been made fully automated so that with the click of the mouse for changing any parameters in the Summary sheet, the entire calculation, and plotting of graphs shall be done automatically.

SUMMARISED DATA

CALCULATION TABLE FOR DISCOUNTED CASH FLOW

SPECIFIC COST/TE

CASE - I (10 MTPA/100 M DEPTH)

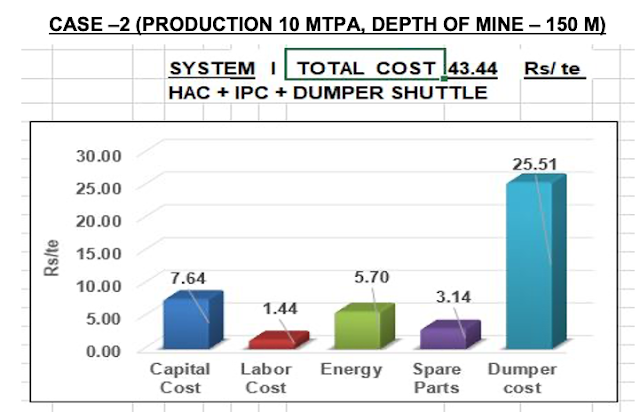

CASE - 2 (10 MTPA/150 M DEPTH)

CASE - 3 (10 MTPA/200 M DEPTH)

The above case studies conclusively prove that DSI SNAKE HAC system shall be the most economic transport system amongst the three systems as mentioned. Opencast mine shall progress deeper and as such, DSI HAC will fetch more savings with the progress of mine. From the above calculation sheets, for the increase of depth from 100 m to 200 m the system cost/te shall increase only around Rs 5.00 per te for DSI HAC (System I), whereas for Dumper transport (System III) the cost shall increase by Rs 35.71. The difference in system cost between DSI Snake HAC (System I) and Dumper transport (System III) for 200 m depth shall be Rs 75.64 per te i.e for 10 mtpa. With the increase of diesel price, the savings will be more.

The cumulative savings in cash flow for DSI HAC (System I) with regard to Dumper transport (System III) for 200 m depth shall be 36533.33 - 5677.43 = 30855.90 MINR in 20 years (pl. see cash flow curve for case 3), whereas the total investment for DSI SNAKE HAC, IPC, and 5 nos. Dumper shall be around 710 MINR (Pl see the summarised data). It will be quite obvious any mine operator/investor shall have no hesitation to adopt DSI Snake HAC transport system. In fact, the above calculation has conclusively quantified the economic gain of DSI Snake HAC. It is very easy to calculate the difference in cumulative cash flow between all the System I, II & III year-wise.

With the increase of production, the economics shall be further in favor of DSI SNAKE HAC. The above calculation has been done based on 2000 mm wide HAC, which may carry @ 2000 t/h. Hence, accordingly the HAC may easily handle @11.8 mtpa. The advantage of any conveyor system over dumper transport is by increasing conveyor speed/width the system can achieve much higher production with much less additional investment and manpower, which is not possible for Dumper transport. Four salient conclusions may be drawn, as follows:

1. DSI SNAKE HAC is the cheapest way of transport of material from pit-bottom to surface in opencast.

2. With the increase of depth and production DSI SNAKE HAC becomes more economic.

3. DSI SNAKE HAC is the most environment-friendly technology.

4. Manpower requirement is minimum for DSI SNAKE HAC system, since, only one conveyor unit can carry the material, whereas, due to zigzag nature of conveyor path, IPC may require nos. of conveyor segment and shall require more manpower.

The DSI Snake HAC is of modular construction and can be easily transported and can be assembled at the site very conveniently. Unlike, the conventional conveyor gantry structure, the HAC system does not require huge structural works to be erected at the site and can be installed/erected with much less time. The idlers and other parts of HAC system can also be resourced in India.

The Author presumes that economics and advantages are clearly understood through the above calculations. In case of any doubt, interested persons are welcome to contact the Author.

MODULAR AND TRANSPORTABLE PART OF DSI SNAKE HAC

The Author is the Technical representative and support person for DSI Santos International, USA in India. Kindly visit the website www.dossantosintl.com for various information and also reference installations. You may send mail INFO@DOSSANTOSINTL.COM.

Any specific quarry may be sent to the Author also for onwards transmission to DSI International.

CMPDI is now proposing DSI Snake in the forthcoming projects. It is expected several projects on DSI Snake HAC technology shall be implemented in India. Hope the above cost calculations shall be very useful and shall help decision-makers to consider DSI Snake HAC in the forthcoming opencast projects.

If the Customer desires, DSI Santos shall help in formalizing the optimum selection of the system. As per their norms, they send their experts to supervise the installation. In addition, the Author is also associated with M/S Development Consultants Pvt. Ltd (DCPL), an Internationally reputed Design organization and we have successfully done project implementation and monitoring for Sasan CHP of Reliance Power, Sonepur Bazari CHP, Workshop & Training Center (World Bank Project under ECL) in past. DCPL is also currently engaged in project implementation & management for Manoharpur opencast under OCPL and Pakri-Barawadi under NTPC. involved in project implementation.

Hence, with the direct guidance and involvement of DSI International, USA, and active participation of DCPL, any DSI Sandwich HAC can be very successfully implemented in India. The spares e.g, idlers, drives, belting is also like conventional conveyor systems and can be indigenously procured.

To conclude, technology shall take the front seat with the Sandwich High Angle Conveyor transport system in opencast mining. This system shall be in perfect harmony with the environment and shall be low carbon haulage system. This system shall eliminate the hazardous transport & operation system of dumpers. This will reduce the chance of accidents. The dumper transport system is not only un-economic but also creates huge dust and smoke pollution not only in mines but also pollute the surroundings. Sandwich HAC system shall enable achieving green mining. In the COVID-19 situation let's all try for creating a pollution-free world.

Author:

Shyamal Kumar Bag

Technical representative of Dos Santos International, US

Retainer Consultant of DCPL

MD of Merchentus India Exim International LLP

www.merchentusindia.com

e-mail: shyamalkumarbag@gmail.com

Mobile: +91 8697002292

Dated, 6th May 2020

Hari Om Dear Samal Da, A fantastic

ReplyDelete